Major wastewater treatment plant works to serve urban metropolis

-

Project type Wastewater

-

Area served Urban; densely populated

-

Population served 5,000,000

-

Status Complete (2017)

The large-scale wastewater treatment plant on Stonecutters Island was upgraded and extended to handle wastewater treatment for over five million Hong Kong residents as part of Harbour Area Treatment Scheme (HATS) Stage 2A. The major infrastructure scheme was implemented to alleviate pollution in the Victoria Harbour, which was having a detrimental effect on water quality and marine life.

The water quality was so poor before the works that beaches were closed to the public and urban developments were being impacted, preventing the long-term sustainable development of the harbour area.

Scheme stages:

- HATS Stage 1 was completed in 2001 and had the capacity to treat 75% of Hong Kong’s urban wastewater

- HATS Stage 2A was completed in 2017 and involved an upgrade and extension to treat the remaining 25% of Hong Kong’s urban wastewater (Biwater project)

- HATS Stage 2B will go on to provide additional biological treatment provisions for the plant

The HATS 2A project won the Wastewater Project of the Year Distinction Award at the 2016 Global Water Awards. The award recognised the wastewater project that showed the greatest innovation in terms of optimising its physical or environmental footprint. HATS Stage 2A was considered an industry success, as “The neat dovetailing of the numerous infrastructure components reflects a uniquely holistic and forward-thinking approach to municipal wastewater and environmental management”.

HATS Stage 2A works included a new chemically enhanced primary treatment (CEPT) facility, which included the construction of a 30m deep intake pumping station and eight double-decked sediment tanks. With land at such a premium in Hong Kong, this optimised design greatly reduced the footprint of the sewage treatment works, while incorporating many environmental features.

As a result of Biwater’s work on HATS Stage 2A, the treatment capacity of the plant has increased from 1,700 MLD to 2,400 MLD and significantly improved the quality of water in the Victoria Harbour, as well as benefitting residents and businesses across Hong Kong.

This project was a technical success story, as major upgrade and extension works took place during ongoing operations of the existing plant to ensure that there was no downtime. At the time of commissioning, the plant boasted the largest sewage pump station in the world.

Edwin Tan, Regional Director, Asia PacificWorks:

View of the double decked primary settlement tanks capable of removing total suspended solids and biochemical oxygen demand contaminants from flows up to 48m³/s

View of the double decked primary settlement tanks capable of removing total suspended solids and biochemical oxygen demand contaminants from flows up to 48m³/s

View of the double decked primary settlement tanks, covered to minimise the visual and environmental impact to the local community

View of the double decked primary settlement tanks, covered to minimise the visual and environmental impact to the local community

Extensive odour management system visible throughout the works

Extensive odour management system visible throughout the works

Tanks that process the effluent before it is discharged via the sea outfall; effluent is pre-treated before release with sodium hypochlorite to meet disinfection standards

Tanks that process the effluent before it is discharged via the sea outfall; effluent is pre-treated before release with sodium hypochlorite to meet disinfection standards

Carbon filter that extracts from the sludge vehicle washing plant to help clean and protect plant equipment

Carbon filter that extracts from the sludge vehicle washing plant to help clean and protect plant equipment

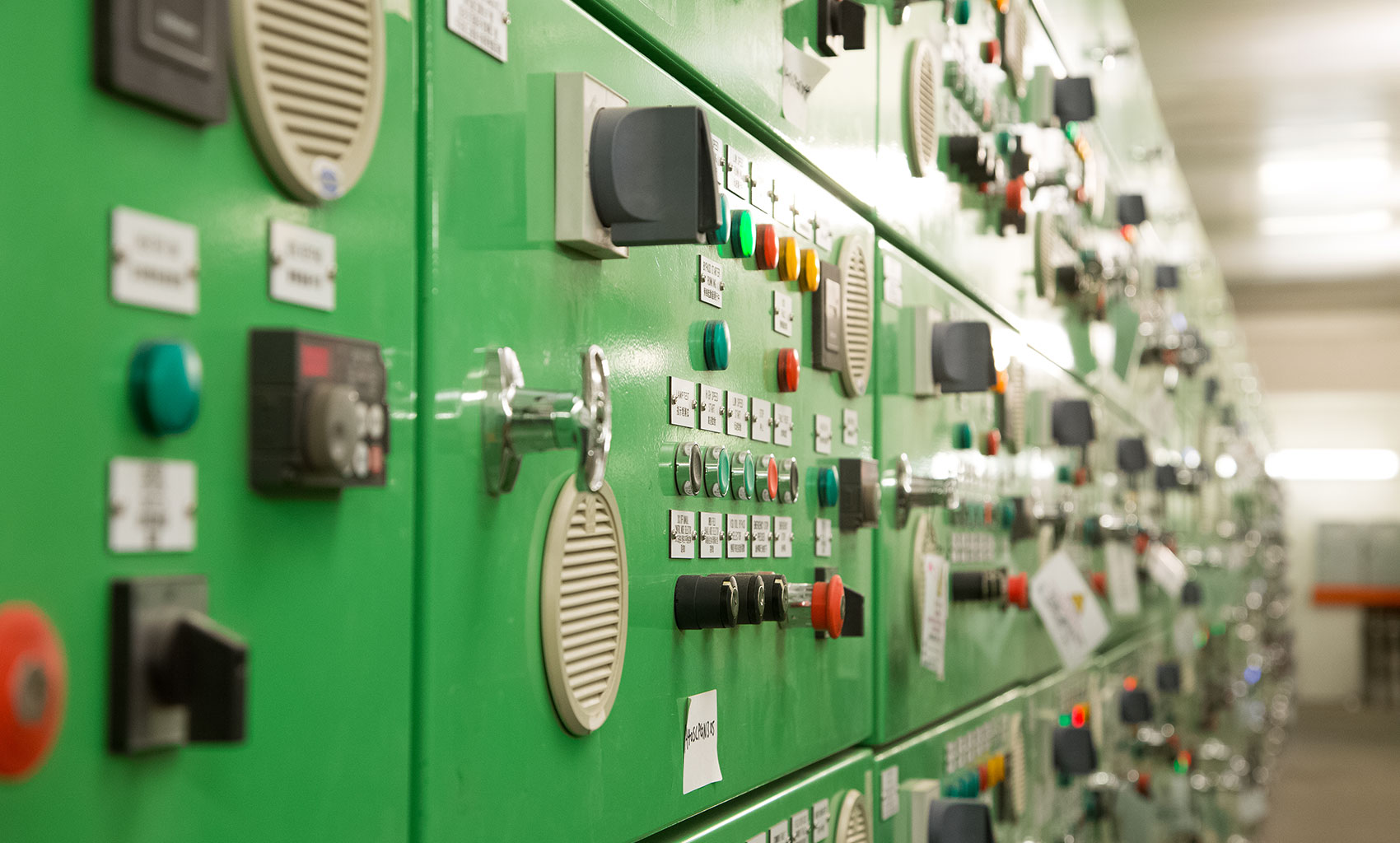

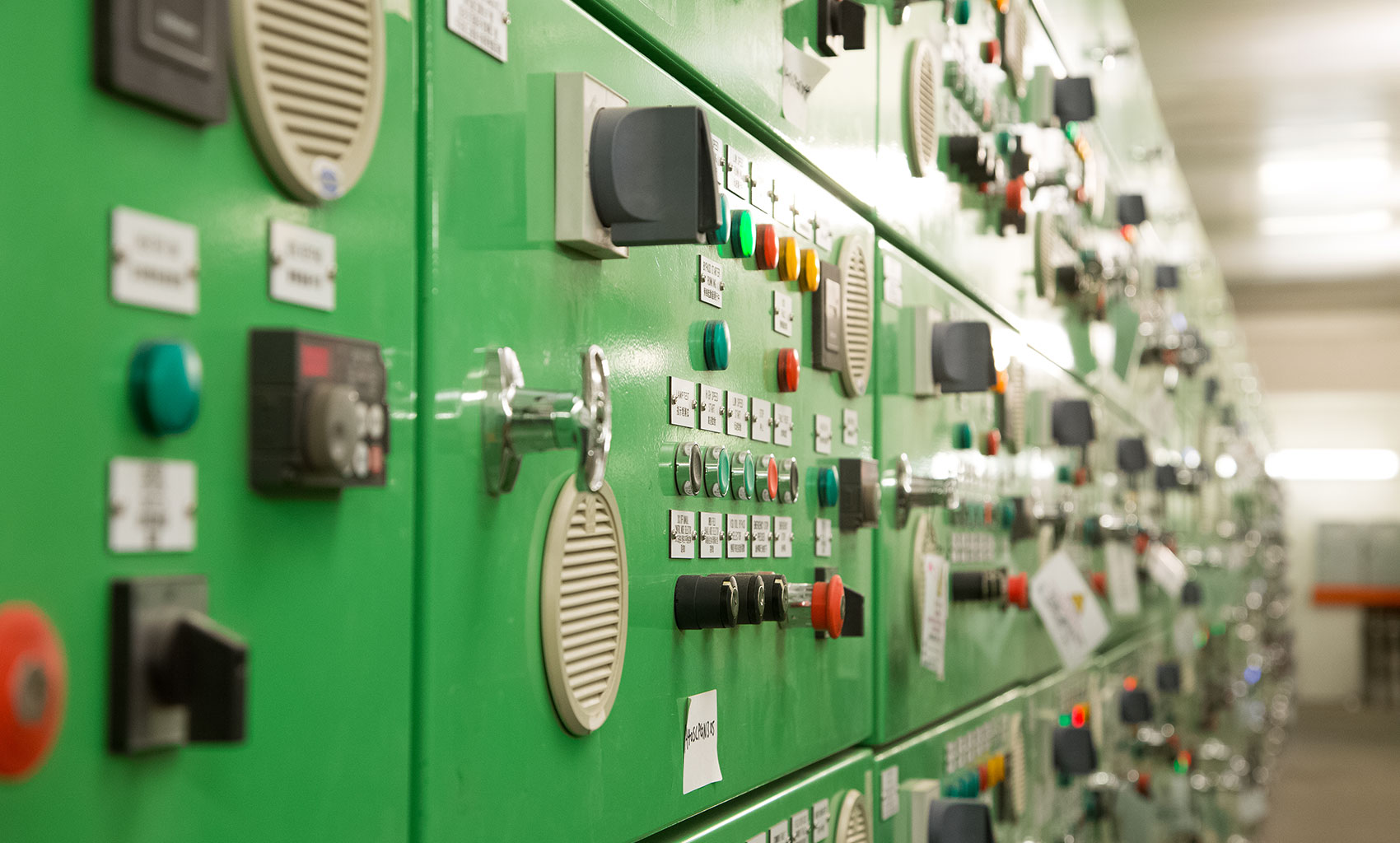

Centralised control room to manage and optimise plant operations

Centralised control room to manage and optimise plant operations

Pumping station with eight pumps capable of transporting 2m3/s of wastewater up to the elevated treatment facility; each pump is driven by a motor unit at ground level

Pumping station with eight pumps capable of transporting 2m3/s of wastewater up to the elevated treatment facility; each pump is driven by a motor unit at ground level

Centralised control centre to manage and optimise plant operations

Centralised control centre to manage and optimise plant operations

One of eight dry well pumps that can carry up to 2m3/s of wastewater up to the elevated treatment facility that is 35m above

One of eight dry well pumps that can carry up to 2m3/s of wastewater up to the elevated treatment facility that is 35m above

Sludge dewatering facility pumps processing sludge at 160m³/hr

Sludge dewatering facility pumps processing sludge at 160m³/hr

Technical summary:

Overview and considerations:

- The completed HATS Stage 2A works, with an overall 2,400 MLD wastewater treatment capacity, provided a fully-flexible and integrated system to accommodate wastewater flows from a wide catchment area. The works have greatly improved CEPT and disinfection processes, safeguarding effluent discharges into the Victoria Harbour

- Biwater was responsible for the construction of a new intake pumping station, CEPT tanks, odour treatment and associated buildings, as well as the design, supply, installation, testing and commissioning of all mechanical and electrical works on the upgrade and extension project

- The existing high voltage/low voltage electrical power supply and distributed control system were upgraded as part of the works package. The control systems were upgraded to accommodate the extension within the existing works, as well as the outlying preliminary treatment facilities located across Hong Kong Island

Wastewater treatment capacity:

- 2,400,000 m3/day

- 2,400 MLD

- 634 MGD US

Highlights of HATS Stage 2A:

- 30m deep intake pumping station

- Finite element analysis was utilised for the design of the knife gate valves for the inlet valve chamber and main pump station

- Two DN3600mm (3.6m) knife gate valves were installed at valve chambers for an interconnection tunnel and inlet valve chamber

- Two DN3000mm (3m) knife gate valves were also be installed for isolation of the wet well from incoming sewage to the main pumping station

- Eight new double-decked sedimentation tanks (new CEPT tank) added to the existing 38 tank arrangement

- Fibreglass perforated energy-dissipating baffles were added to all existing and new tanks to enhance chemical treatment performance; computational fluid modelling techniques and on-site performance verification tests were used to finalise the baffle designs

- A space-saving double-decked design was adopted for all the sedimentation tanks to reduce the plant footprint

- Odour collection and treatment for the extension facilities

- Major upgrade of the distributed control systems and management reporting facilities

Request more information about our projects